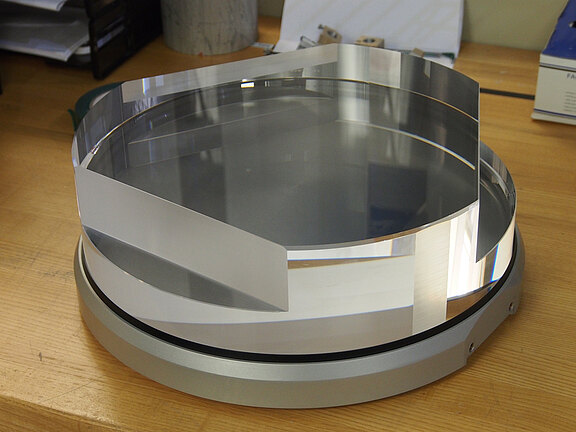

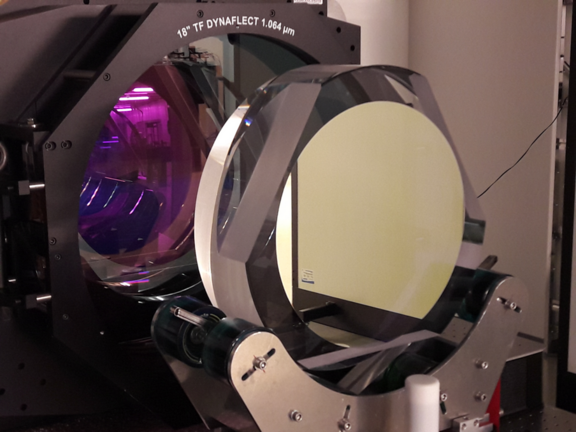

VTF required two etalons (Fabry-Pérot interferometers) with a free aperture of 250 mm, making them the largest etalons ever manufactured. Developing the etalons meant breaking new scientific and technological ground. Each interferometer consists of two plates of high-purity quartz glass measuring 350 mm in diameter and 100 mm in thickness which are arranged at a gap of 0.55 mm and 0.214 mm, respectively. The distance can be adjusted at the nanometre range using piezoelectric actuators. The inner sides of the plates are covered with a partially reflective layer with a reflectivity of 95 % +/- 1 % or 84 % +/-1 %. The plate coating has to be extremely homogeneous. Together with an interference pre-filter, the etalons act like a spectral filter with a half-width value of 6 pm (60 mÅ) at any wavelength between 520 nm and 870 nm. The scanning range or free spectral range is given by the distance between the two etalons and the width of the pre-filter, varying between 0.4 nm and 1.0 nm (from short to long wavelength).

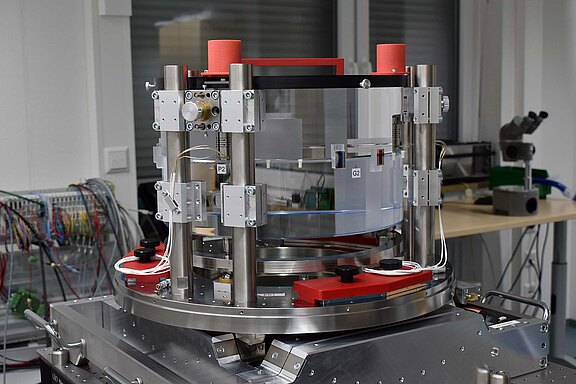

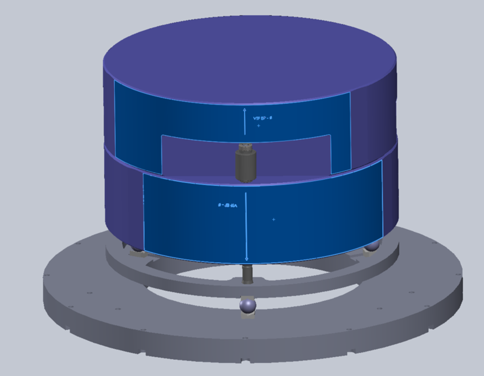

In order to guarantee the homogeneity of the filtergrams over a field of view of one minute of arc, the distance between the plates of both etalons must be constant to better than 3 nm rms (on scales larger than 1 mm). This is why the etalons are mounted horizontally in order to keep the influence of gravity on the gap as homogeneous as possible. The micro-roughness of the optical surfaces must be better than 0.3 nm rms after coating (on scales smaller than 1 mm). These extremely demanding requirements were met after a complex development process in close cooperation with industrial partners. The metrology of the disc distance was carried out with optical encoders which had been qualified at the institute for a precision of 0.1 nm. KIS delivered both the integration and qualification of the etalons and the development of the complex controller for setting the plate spacing.

The following industrial partners collaborated in the development and manufacture of Etalon components: Zygo Ametek, Richmond, Ca, USA (optical processing and measurement of the plates); LMA, Lyon, France (plate coating and measuring); Physik Instrumente, Karlsruhe, Germany (piezo actuators); Heidenhain, Traunreut, Germany (optical encoder).